| Tin Lead Solder Wire 40 60, scientifically known as Solder Wire Sn40Pb60, is a soldering materialcomposed of 40% tin (Sn) and 60% lead (Pb). Solder Wire 40 60 is meticulously formulated by blending specific proportions of tin and lead, chosen for their complementary properties that contribute to effective soldering. As the results of good solderability with its affordable cost, it has been widely in many applications. |

Alloy Composition | 40% Tin (Sn), 60% Lead (Pb) |

Melting Point | 183-247°C |

Flux Type | Rosin based |

Flux Content | 2.0% as standard, or customized flux percentage |

Wire Diameter | 0.5mm to 3.2mm |

Weight | 100g/roll, 200g/roll, 500g/roll to 1kg/roll or customized weight |

Brand | XF Solder or OEM service |

*We also produce solid wire without flux core | |

Various Roll Weights | Flux Core Wire | Various Wire Diameters |

Medium Melting Point The solder wire 40/60 has a higher melting point than solder wire 63/37, making it suitable for components or devices that requires a bit higher working temperature. | Easy to Use Solder Wire 40 60 contains a rosin flux core, that means it can be used directly for soldering and no need to add any external flux. | |

Good Performance The solder wire Sn40Pb60 has good wetting and flowing property, it can form a round, smooth and form solder joints. | Cost Effective The cost solder wire 40 60 is much lower than solder wire 63/37 or lead free solders, it can cut down the manufacturing cost. |

Electronics and electrical devices production: that is mainly for assembly for all types of PCB and joinery for different IC components together. Such as home appliances, wearable electronics devices, electrical parts etc.

General soldering purpose: That is for some repairing work of electronics or electrical products, and some small projects of lobbyists.

Plumbing system: it's used to join the copper pipes and copper fittings for the plumbing systems.

Radiators: it's used for assembling the copper and brass radiator end plates.

Stained Glass: it's used for soldering of the lead came of the stained glass for create shapes and looks.

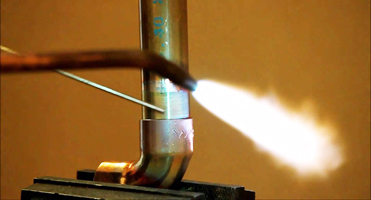

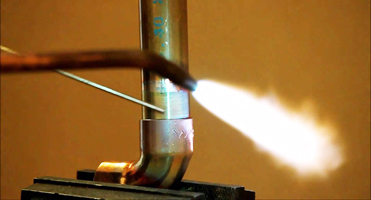

Raditator Soldering |  Plumbing Soldering Plumbing Soldering | Electronics Soldering |

When using solder wire 40 60 for electronics assembly, we recommend to use the rosin flux core type. It's a handy formula that contains flux inside the wire, and there is no need to apply external flux when doing the soldering task. We will need soldering irons or soldering stations to carry out the soldering process.

When suing solder wire Sn40Pb60 for plumbing systems or radiators assembly, we recommend to use the solid wire without flux core, and then prepare compatible strong flux in separate for the soldering. And we will need torch gun to do this soldering process.

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.

| Tin Lead Solder Wire 40 60, scientifically known as Solder Wire Sn40Pb60, is a soldering materialcomposed of 40% tin (Sn) and 60% lead (Pb). Solder Wire 40 60 is meticulously formulated by blending specific proportions of tin and lead, chosen for their complementary properties that contribute to effective soldering. As the results of good solderability with its affordable cost, it has been widely in many applications. |

Alloy Composition | 40% Tin (Sn), 60% Lead (Pb) |

Melting Point | 183-247°C |

Flux Type | Rosin based |

Flux Content | 2.0% as standard, or customized flux percentage |

Wire Diameter | 0.5mm to 3.2mm |

Weight | 100g/roll, 200g/roll, 500g/roll to 1kg/roll or customized weight |

Brand | XF Solder or OEM service |

*We also produce solid wire without flux core | |

Various Roll Weights | Flux Core Wire | Various Wire Diameters |

Medium Melting Point The solder wire 40/60 has a higher melting point than solder wire 63/37, making it suitable for components or devices that requires a bit higher working temperature. | Easy to Use Solder Wire 40 60 contains a rosin flux core, that means it can be used directly for soldering and no need to add any external flux. | |

Good Performance The solder wire Sn40Pb60 has good wetting and flowing property, it can form a round, smooth and form solder joints. | Cost Effective The cost solder wire 40 60 is much lower than solder wire 63/37 or lead free solders, it can cut down the manufacturing cost. |

Electronics and electrical devices production: that is mainly for assembly for all types of PCB and joinery for different IC components together. Such as home appliances, wearable electronics devices, electrical parts etc.

General soldering purpose: That is for some repairing work of electronics or electrical products, and some small projects of lobbyists.

Plumbing system: it's used to join the copper pipes and copper fittings for the plumbing systems.

Radiators: it's used for assembling the copper and brass radiator end plates.

Stained Glass: it's used for soldering of the lead came of the stained glass for create shapes and looks.

Raditator Soldering |  Plumbing Soldering Plumbing Soldering | Electronics Soldering |

When using solder wire 40 60 for electronics assembly, we recommend to use the rosin flux core type. It's a handy formula that contains flux inside the wire, and there is no need to apply external flux when doing the soldering task. We will need soldering irons or soldering stations to carry out the soldering process.

When suing solder wire Sn40Pb60 for plumbing systems or radiators assembly, we recommend to use the solid wire without flux core, and then prepare compatible strong flux in separate for the soldering. And we will need torch gun to do this soldering process.

Use in a Well-Ventilated Area: Always solder in a well-ventilated space, such as a fume hood or near an open window, and use exhausting fan. Proper ventilation helps to dissipate harmful fumes and reduce the risk of inhaling lead vapors.

Wear Personal Protective Equipment (PPE): Consider wearing appropriate personal protective equipment, including safety glasses, gloves, and a lab coat or apron, to minimize skin and eye contact with solder and flux.

Avoid Ingestion and Hand-to-Mouth Contact: Never eat, drink, or smoke while working with leaded solder. Wash your hands thoroughly after handling solder and before eating or touching your face.

We are a professional manufacturer of 1mm 2mm 60 40 Soldering Wire Resin Cored 450grm 1kg 250g 500 gm for Online Shop Sell from China. It's the art of crafting durable, precise, and reliable connections. Introducing our 60/40 resin-cored solder wire, designed to elevate your soldering experience with a fusion of performance, convenience, and versatility. Whether you're a seasoned professional or a passionate hobbyist, this solder wire is your go-to solution for flawless results.

Our 50/50 Tin-Lead Solder Paste offers a perfect balance of performance and reliability for SMD assembly. Whether you're looking for superior wettability, strong joint formation, or dependable conductivity, this product is your trusted partner in achieving top-tier results in electronics manufacturing.

Sn40/Pb60 soldering lead, composed of 40% tin and 60% lead. Offered in versatile diameters of 1mm and 2mm, and conveniently packaged in 250g reels, this alloy is a reliable solution for various electronics soldering applications. Its balance of cost-efficiency, reliability, and versatility makes it an excellent choice for a variety of soldering applications.

We are a manufacturer of Lead-Free Solder Paste Sn96.5/Ag3/Cu0.5 (96.5% Tin, 3% Silver, 0.5% Copper) for Surface Mount of Printed Circuit Boards from China. The tin content (96.5%) provides excellent melting characteristics, while the 3% silver enhances mechanical strength and solder joint reliability. Copper (0.5%) further stabilizes the alloy and contributes to improved thermal and mechanical properties, ensuring that it meets the demands of printed circuit board assembly by surface mount.